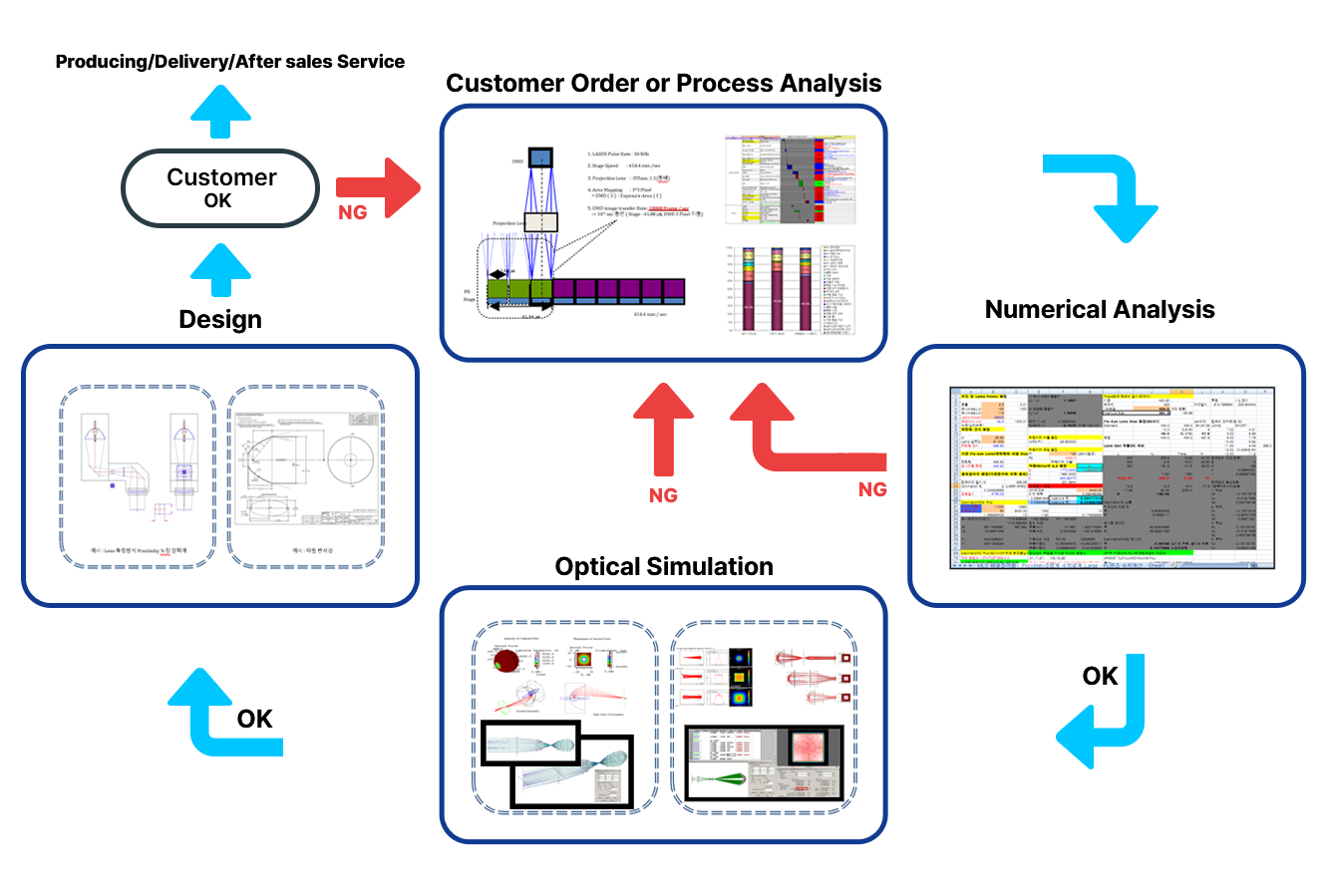

By analyzing the customer’s optical production and requested technology, we provide the best optimized optical system to satisfy their needs with our optical expertise and experience database.

We provide support by maximizing the optical efficiency of the optimal light source and

optical system to dramatically improve productivity (tact time) compared to existing lines.

We maximize productivity by supporting a high-output optical system using multiple light sources.

Example : By replacing the light source of the exposure process line (ultra-high pressure mercury lamp, other bulb lamp type light source)

with an LED light source, investment costs are reduced by excluding equipment related to cooling of heat generation from existing lamps

(ex. lamp houses, cooling systems, and exhaust system).

During production, cooling, exhaust UT costs/electricity costs, and more are also reduced. Moreover,

reducing replacement costs with an extended service life compared to mercury lamps, and minimizes losses due to

equipment stoppage by extending the replacement cycle.

Costs are reduced by improving yield due to product deformation and defects by heat generation from existing lamps do not occur.

It is harmless to the human body as there is no ozone generated by UV rays with a wavelength of 185nm,

and there is no risk of explosion due to poor cooling of existing lamps.

Example : Dramatic improvement in light quality (NA of irradiated light, uniformity, optical angle, etc.)

If you need high-resolution and high-quality products, we support optical systems that irradiate light close to your ideal.

If you require light sources of various wavelengths and special functions, we provide the necessary light sources and optical system.